how to use a water jet cutter

It does not generate heat making it suitable for heat-sensitive materials. The first small waterjet cutter in a compact package.

The Design And Development Of The First Ever Low Cost Waterjet Cutter Youtube

Avoid cutting the air gap larger than 05 mm.

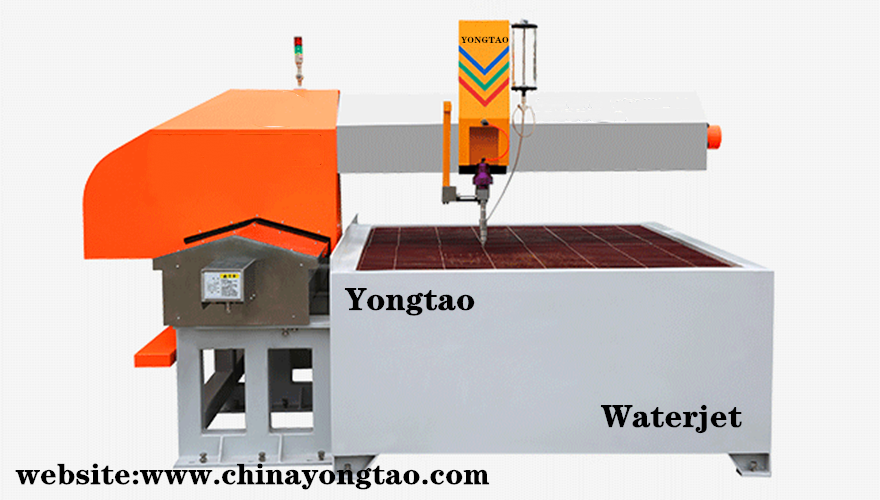

. A waterjet cutter also known as a waterjet cutting machine is a cutting machine that harnesses the power of pressurized water typically mixed with an abrasive material. The smaller orifice the smaller the cut width kerf. The smaller orifice the smaller the cut width kerf.

The process is used to produce name plates signage and company logos. Hard materials like metals composites plastics and alloys usually require the addition of an abrasive in the. It is possible to cut any type of stone using waterjet technology.

Air gap encountered during cutting. Stone can be cut using a water jet cutter to make a variety of carvings. Water jet cutting is one the most common industrial cutting methods for engineered stone thick granite.

The high pressure of the water jet cuts. Water jet cutting is used to create permanent name plates out of heavy metals. I show the basics of what a w.

Yes it is possible and very easy to cut foam with a waterjet cutter. Water jet cutting of rubber finds applications in a number of industries such as automobiles office products agricultural equipment recreational equipment aerospace. Yet its still industrial grade enough to CNC cut steel.

After all leversswitches have been turned on in proper order then hit the reset button on the. I was getting a lot of questions about how the Flow Mach 500 waterjet works so I decided to answer all of them with this video. Aluminum waterjet cutting involves a cutting head that emits a high-pressure jet of water focused on the material that requires cutting.

Artwork custom patterns unique designs and logos can all be manufactured. A water jet cutter is a device capable of cutting right into metal or other materials utilizing a jet of water at high speed rate and pressure. Startup machine using the appropriate start up process.

The nozzle is easy to diverge in the air gap so the surface will be very rough when cutting. Industrial water jet cutting though is a non-thermal process. The diameter of the orifice helps determine the cut width kerf.

The inventors of this device had three goals1 To generate pressure up to at least 94000 psi. The process is used to produce name plates signage and. Heres to give you a good sense of the structure of water jet cutter and how it works.

With the cutting accuracy of 01 to 02mm Waterjets become the tool of choice when making internal cut outs. Tips for Your DIY Water Jet Cutter. Using a ruby or diamond jewel the orifice focuses the high-pressure water.

Cnc Waterjet Cutting Machine From Water Jet Sweden

Water Jet Cutting Machine Water Jet Cutting System

Sustainability And Waterjet Cutter Woodguide Org

Turning A Waterjet Cutter Into A Wood Lathe For No Reason Hackaday

How Waterjet Helped Nashville Designer Omax Waterjet

How To Choose The Right Waterjet Cutting Machine

Custom Water Jet Cutting Get A Quote Woodland Manufacturing

C4020 3x Waterjet Cutting Machine For Sale Same Waterjet

Benefits Of Waterjet Cutting Fast Quality Resato

Waterjet Cutting Process Benefits And Materials Explained Fractory

Pressure Matters In Abrasive Waterjet Cutting

The Cutting Edge Of Mishimoto Wardjet Water Jet Cutter Mishimoto Engineering Blog

Abrasive Water Jet Machining How Water Jet Cutter Works

Personal Waterjet Cutter For The Small Shop Fabricating And Metalworking

Small Format Waterjets On The Rise

Cnc Water Jet Cutting Machine For Sale Small Waterjet Cutting Machine

Water Jet Cutting Norwood Medical

5 Fast Facts About Water Jet Cutting Cutting Onemonroe

What Are The Benefits Of Using Waterjet Technology For Precision Cutting